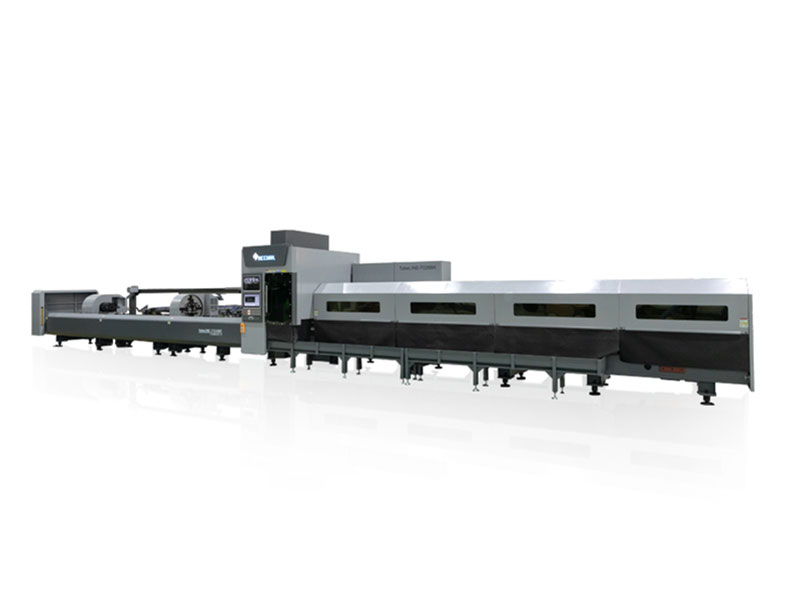

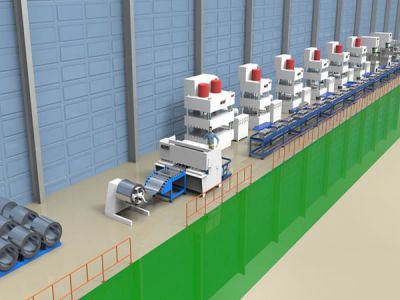

Medium-heavy Three-chuck Tube Laser Cutting Machine, BK Series

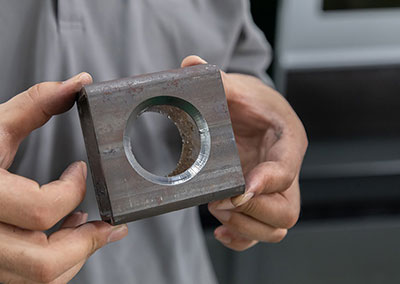

Our tube cutting machines are designed for precision and versatility, enabling efficient cuts across various tube profiles and materials, such as metals and composites. These laser cutting systems are tailored to meet the needs of industries like automotive, construction, and aerospace, where accuracy and speed are important. Thanks to its advanced features designed to minimize waste and maximize productivity, our tube cutters are ideal for environments with frequent production changes, ensuring consistent results with every cutting process.

| Model | TubeLINE-6020BK | TubeLINE-7028BK |

| Power | 3000W/6000W | |

| Processing range | Ø12-200mm L: 12-140mm | Ø12-280mm L: 12-200mm |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.05mm | ±0.05mm |

| Max. no-load running speed | 100m/min | 100m/min |

| Max. idle speed | 100r/min | 100r/min |

| Max. weight of single tube | 250kg | 250kg |

| Feeding dimensions | ≤3000mm | ≤3000mm |

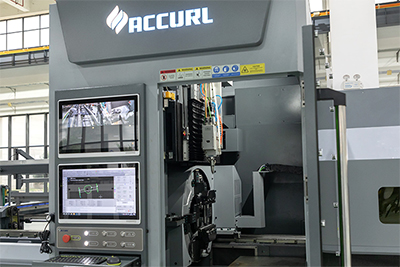

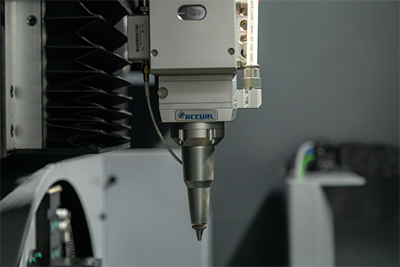

This module integrates advanced tube support with a precision straightening mechanism to combat sagging and reduce rotational friction effectively. It includes a concave adjustment device to protect tubes against bending and impact during operation, enhancing both safety and efficiency.

This system features a versatile pneumatic support that adjusts to accommodate various material types, ensuring precise alignment with the chuck to mitigate sway. The optional servo-driven support enhances cutting accuracy, providing a significant advantage over traditional reducer wheel systems in tube cutting scenarios.