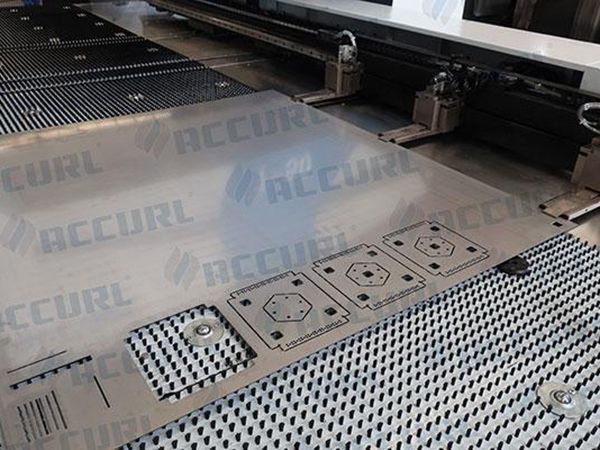

50 Ton CNC Servo Driven Ram Turret Punch Press

A punching machine that converts your workshop into one with the highest productivity

ACCURL®MAX-SF Series CNC punch press machine is a new generation for servo hydraulic turret punch presses, utilizing the same features of a high reliability and durability as previous generations. With a German H + L advanced servo hydraulic system, its punching capacity remains strong, even for thick sheets. Offering multiple functions for punching, forming, roller cutting, and tapping, stand by time and material usage are significantly improved. Further, the high speed and accuracy, energy saving and integrated construction reduce maintenance costs.

- Advanced CNC Hydraulic Servo system with pressure valve to precisely control the speed, volume and pressure of oil flow.

- To control the RAM stroke distance on both ends, hence the height and depth of each punch becomes programmable with 0.1mm accuracy.

- Uniquely designed Machine structure ensures less preventive maintenance

- The AC punch servo motor can be programmed for various applications.

I) High speed applications.

II) Low noise applications.

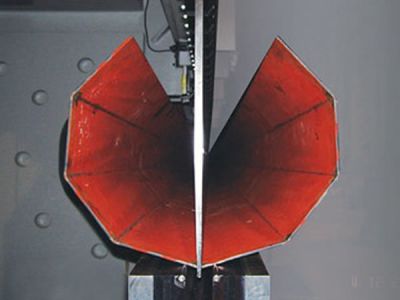

III) Forming applications. - The punch servo utilizes a direct drive gearbox that supplies power and speed, the servo allows the user to steplessly adjust the punch stroke and accommodate any pressure curve requirements.

- Synchronized dual servo motors for controlling the auto index functions.

- 2 D Auto Index Stations for Multi Tools, either 3 B or 8 A.

- Capable of indexing each individual tool within the 3B and 8A Multi Tool set.

- 24 various size stations including 4 Auto Index stations Multi Tools. Therefore, a total of 24 to 52 tools can be employed.

- Capable of running wheel, marking, grooving and forming Tooling.

- The ACCURL is compatible with thick turret tooling,and the wide variety of specialty tools combined with the programmable ram means the ACCURL can deliver for any application.

| TURRET CONFIGURATION | |||||

| Turret Configuration | A | B | C | D | D-AI |

| 32 Station-2 Auto Index | 16 | 12 | 2 | 0 | 2 |

| 32 Station-3 Auto Index | 16 | 12 | 1 | 0 | 3 |

| 42 Station-4 Auto Index | 20 | 16 | 2 | 0 | 4 |

| 52 Station-2 Auto Index | 30 | 14 | 4 | 2 | 2 |

- Accurl Direct Drive servo punch system

- Fanuc CNC and high precision absolute encoder, dynamic, brushless alfa series servo motors

- 3 automatic repositioning clamps and loading switches.

- FANUC Series Oi-PO CNC Control System

- Aluminum workholder

- Tool lubricating system (Airblow).

- Free standing control panel.

- Control with foot pedal.

- Tools stuck safety system

- 1 software (Lantek or RADAN software).

- 24 or 42 turret stations

- Digital oil temperature indicator.

- Software for using wheel and forming tools.

- Sheet jumping switches

- Scrap box.

- Chain protection around the machine (safety system).

| Item | Unit | MAX-SF-50T |

| Punching Capacity | Ton | 50 |

| X Traverse Length | mm | 2500±10 |

| Y Traverse Length | mm | 1250±10 |

| Max Sheet Size | mm | 1250x4980 |

| Max Sheet Thickness | mm | 8.35 |

| Max Sheet Weight | kg | 110 |

| X Axis Traverse Speed | m/min | 100 |

| Y Axis Traverse Speed | m/min | 80 |

| Max Traverse Speed | m/min | 128 |

| Punching Speed at 25mm pitch* | hist/min | 450 |

| Nibbling Speed | hist/min | 1200 |

| Tools Type | Thick turret | |

| Max Punching Diameter | mm | 88.9 |

| Number of Tool Stations | 32 / 42 / 52 | |

| Number of Auto Index Stations | pcs(type) | 4(2B+2C) / 3(2B+1C) / 2(1B+1C) |

| Turret Rotating Speed | rpm | 33 |

| Auto Index Rotationg Speed | rpm | 100 |

| Ram Stroke Distance | mm | 0~31 |

| Working Tables Size | Brush | |

| Number of Sheet Clamps | pcs | 3 |

| Air Supply | NL/min | 250 |

| Air Supply | bar | 6 |

| Oil Tank Volume | Litre | 275 |

| Machine Dimension (L x W x H) | mm | 5940x5220x2420 |

| Net Weight (approx.) | kgf | 15,000 |

| Size of Control Cabinet | mm | 1350x700x2185 |

| CNC Controller | FANUC Oi-PD | |

| Number of Controllable Axes | Axis | 4 |

| RAM Memory | KB | 512 |

| Serial Interface | RS232/RJ45/PCMCIA | |

| Punching Precision* | mm | ±0.1 |

- Specifications are subject to change without prior notice.

- Acceleration / deceleration rate of X / Y-axis are dependent on weight of materials.

- Punch speed depends on processing conditions, stroke length, acceleration / deceleration of axes speeds.