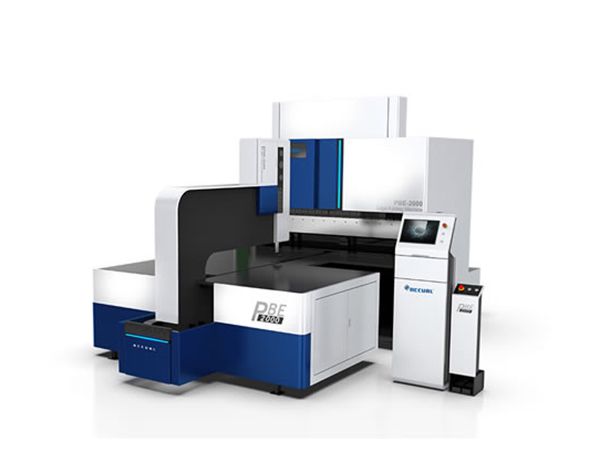

Panel Bending Machine

The PBE series panel bender represents the next generation of automated bending technologies and serves as a benchmark for the industry's transition to automation in sheet metal fabrication. It can significantly reduce labor costs while achieving 300% higher efficiency than traditional bending machines, with bending times of up to 0.3 seconds per bend. The precision is significantly improved by closed-loop BUS control and full electro servo transmission.

The multilateral bending center does not need to change the mold, the working stroke is short, and the feed is fast.

It can be automatically folded up and down in accordance with the bending process to accomplish the bending of arcs, dead edges, and varied angles.

Highly intelligent operation control system is adopted so that different workpieces can be bent effectively.

| Name | Unit | PBE-1400 | PBE-2000 | PBE-2500 | |

| Max. Bending Length | mm | 1400 | 2000 | 2500 | |

| Max. Sheet Width | mm | 1500 | 1500 | 1500 | |

| Max. Bending Height | mm | 170 | 170 | 170 | |

| Min. Workpiece Size (four sides bending) | mm | 110x200 | 110x200 | 110x200 | |

| Min. Workpiece Size (single side bending) | mm | 110 | 110 | 110 | |

| Min. Radius | mm | 1.2 | 1.2 | 1.2 | |

| Bending Angle | ° | ±180 | ±180 | ±180 | |

| Max. Bending Speed | s/bending | 0.5 | 0.5 | 0.5 | |

| Min. Sheet Thickness | mm | 0.35 | 0.35 | 0.35 | |

| Max. Sheet Thickness | SS | mm | 1.0 | 1.0 | 1.0 |

| MS | mm | 1.5 | 1.5 | 1.5 | |

| AL | mm | 2.0 | 2.0 | 2.0 | |

| Dimensions(L×W×H) | mm | 3100x5300x2600 | 3100x6050x2600 | 3100x6050x2600 | |

| Full Power | kW | 45 | 45 | 45 | |

| Working Voltage | V | 380V±10% | 380V±10% | 380V±10% | |

-

-

Multi Positioning Ways

The servo motor controls the movement of the positioning L-block, which is fast and accurate.

-

-

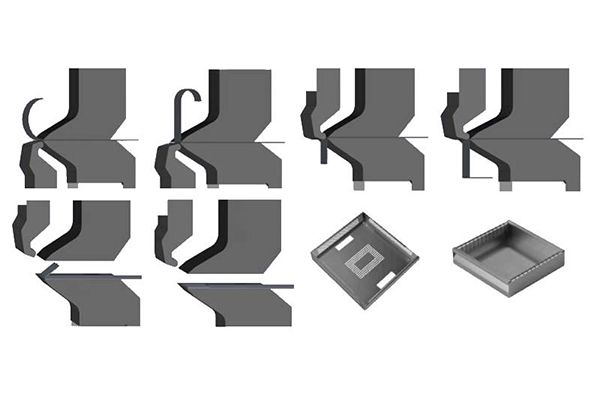

Universal Tooling

The standard bending tool is powerful, which can realize both UP and DOWN bending process, without rotate the sheet. It can also perform HEM bending and big ARC bending automatically.

-

-

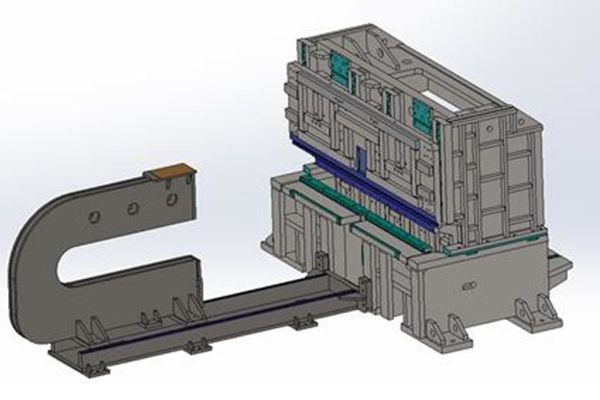

Plate Welding Frame

The servo motor controls the movement of the positioning L-block, which is fast and accurate.

-

-

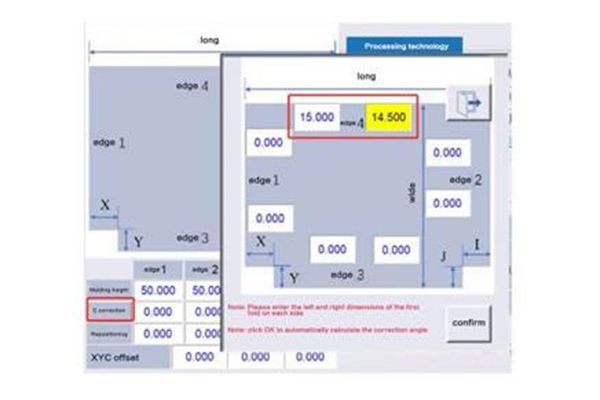

Automatic Correction of Rotation Angle

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

-

-

Controlling System

In view of the high-intensity motion requirements of the panel bender, the frame adopts an arch design, which is thickened and widened. The frame is tempered, annealed and aged twice to ensure the long-term running accuracy, stability and high rigidity of the bending machine.

-

-

Servo System

The pure electric servo fully closed-loop system is adopted, and the system supports up to 16 axes concurrent linkage, so that the bending action is smooth, the mechanical operation is highly coordinated, and the combination of various complex actions can be smoothly realized. The whole bending machine has high working efficiency and low daily maintenance workload. It has a self-lubricating system for the whole machine. When the oil amount is lower than the specified value, the system will automatically alarm. Just follow the program prompts to add lubricating grease.